Printable PDF About Polybutlene Piping

Polybutylene piping is found in homes and condominiums in our area that were built between 1978 and 1995 and can be a disaster waiting to happen.

The following information is deemed reliable but should not be your sole source for decisions you make.

Polybutylene piping is found in homes and condominiums in our area that were built between 1978 and 1995 and can be a disaster waiting to happen. The pipes can burst without notice causing catastrophic flooding in the dwelling. They are often difficult to locate because most plumbing piping is in walls, under slabs or in the attic under insulation. In many instillations where the pipes penetrate the walls at hose faucets or under vanities copper piping is attached to the end of polybutylene piping (poly pipe) hidden in the wall.

Property Values, Ownership, and Buyer Notification

Property Values, Ownership, and Buyer Notification

When a home containing poly piping is placed on the market, buyers will often discount the price (due to the material defect) – even if the poly has not yet shown any leaks – because it is known that poly piping will leak eventually. A wise seller would replace any poly piping before putting a house on the market. There are currently no laws regarding the disclosure of poly piping on a property, but some Real Estate brokers have been sued for not disclosing its presence in buildings they sell. At the very least, both sellers & buyers should be provided with some sort of information regarding poly piping and its dangers.

Costs do vary but removal and replacement of poly piping will typically cost between $4,000.00 and $8,000.00 dollars and take 5 days. New pipes are run through the attic with some cuts necessary in the walls. The home can usually be lived in during the renovation procedure with water being restored each night.

Polybutylene piping is not a deal killer. Many of the homes in our area which have poly pipes do not have the problem fitting and there is not a current concern. In others adjustments may be made as with any unknown concern that is found in an inspection. The most important thing is to be knowledgeable and impart that knowledge to your customer so there are no surprises during or after the sale.

A History of Polybutylene Piping

Polybutylene is a form of plastic resin that was used extensively in the manufacture of water supply piping from 1978 until 1995. Due to the low cost of the material and ease of installation, polybutylene piping systems were viewed as "the pipe of the future" and were used as a substitute for traditional copper piping. It is most commonly found in the "Sun Belt" where residential construction was heavy through the 1980's and early-to-mid 90's, but it is also very common in the Mid Atlantic and Northwest Pacific states.

These are typically gray or white in color with a dull finish. The piping systems were used for underground water mains and as interior water distribution piping. Industry experts believe it was installed in at least 6 million homes, and some experts indicate it may have been used in as many as 10 million homes. Most probably, the piping was installed in about one in every four or five homes built during the years in which the pipe was manufactured.

How to Tell If You Have Poly

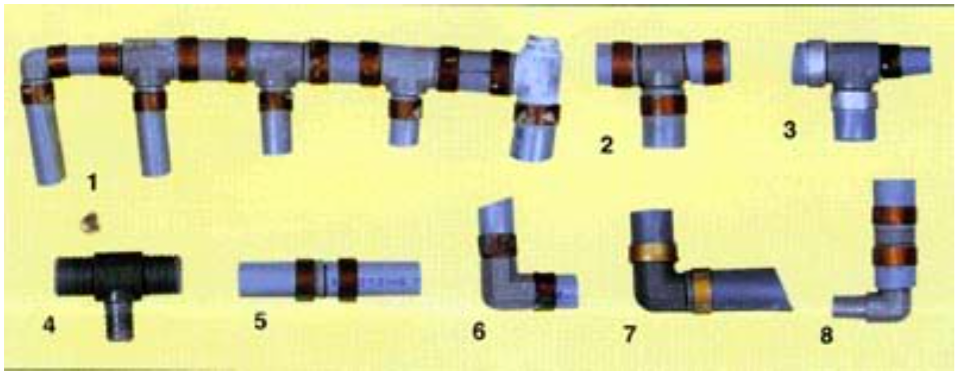

Exterior - Polybutylene underground water mains are usually blue, but may be gray or black (do not confuse black poly with polyethelene pipe). It is usually 1/2" or 1" in diameter, and it may be found entering your home through the basement wall or floor, concrete slab or coming up through your crawlspace; frequently it enters the home near the water heater. Your main shutoff valve is attached to the end of the water main. Also, you should check at the water meter that is located at the street, near the city water main. Interior - Polybutylene used inside your home can be found near the water heater, running across the ceiling in unfinished basements, and coming out of the walls to feed sinks and toilets. Warning: In some regions of the country plumbers used copper "stub outs" where the pipe exits a wall to feed a fixture, so seeing copper here does not mean that you do not have poly. See the photos below of polybutylene pipes and fittings.

Will the Pipes Fail?

While scientific evidence is scarce, it is believed that oxidants in the public water supplies, such as chlorine, react with the polybutylene piping and acetal fittings causing them to scale and flake and become brittle. Micro-fractures result, and the basic structural integrity of the system is reduced. Thus, the system becomes weak and may fail without warning causing damage to the building structure and personal property. It is believed that other factors may also contribute to the failure of polybutylene systems, such as improper installation, but it is virtually impossible to detect installation problems throughout an entire system. 3 types of fittings were known to have been used with the earlier fitting more prone to failure.

Throughout the 1980's lawsuits were filed complaining of allegedly defective manufacturing and installation causing hundreds of millions of dollars in damages. Although the manufacturers have never admitted that poly is defective, they have agreed to fund a Class Action settlement with an initial amount of $950 million. You'll have to contact the appropriate settlement claim company to find out if you qualify under this settlement.

Typical piping & fittings